- Services

- Laboratory services

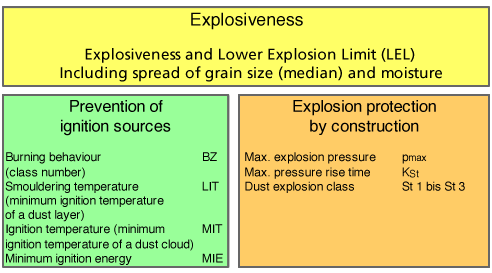

- Flame and explosion characteristics

Flame and explosion characteristics of dusts

DEKRA determines values relevant for measures of explosion protection

Knowing the flame and explosion characteristics of inflammable is necessary for handling those materials safely. Such characteristics are relevant for

- Operators of systems and plants who have to choose and assess appropriate measures of explosion protection within the scope of hazard assessment according to the Regulations of Occupational Safety (explosion protection document).

- Manufacturers and planners of systems and plants who have to define a concept of explosion protection as part of their engineering.

- Manufacturers of dust-type products (bulk goods) which have to state details of dust explosion hazards in the safety data sheets of their products in the paragraph "Physical and chemical properties".

The type and volume of the tests are always adapted to each specific case (e.g. plant, procedure, process conditions and organisational measures). In particular, processes of segregation or enrichment of fine dust have to be considered. Otherwise, the assessment of hazards or explosion protection measures may be misinterpreted.

Do not hesitate to contact us if you have any questions regarding this point.

Parameter packages

Our work is based on the following principle: "We only determine what you really need – and are there to support you with our expertise."

Therefore, we offer suitable packages of parameter determination as a kind of starter kind for hazard assessment. In addition, we will be able to carry out all types of parameter determination and specific further examinations.

| Issue | Pckg. | Refenrences & Advantages |

|---|---|---|

| Data of explosion protection needed for safety data sheet

Flame and explosion characteristics not known at all Design of a comprehensive concept for explosion protection including measures of protection by prevention and by construction |

Package “Complete determination”

|

|

| Dust not likely to be explosive (coarse, low proportion of fine dust or high proportion of inert material)

Are measures of explosion protection to be carried out at all? At which proportion of inert material is a dust mixture not explosive? |

Package “Explosiveness”

|

|

| The dust is explosive.

Are preventive measures of explosion protection sufficient? What must the design of electrical and non-electrical equipment look like with regard to their maximum surface temperature? |

Package “Prevention of ignition sources”

|

|

| The dust is explosive.

The result of the hazard assessment shows that an explosion inside the system or plant cannot be safely excluded (e.g. smouldering nests may enter the system). Thus measures of construction are necessary to ensure safe plant operation. |

Package “Explosion protection by construction”

|

Specific examinations

For all packages you can choose additional examinations that may be relevant for particular issues. Those examinations include the following:

| 1-m³ vessel | Beside the standard testing device of the 20-l sphere we also offer a determination of characteristics using a 1-m³ vessel. This larger testing device is often the only opportunity to examine dusts and fibres which are coarse and difficult to stir up. |

| Limit concentration of oxygen |

The limit concentration of oxygen is measured to determine the parameters for inerting plants and procedures. |

| Increased temperature |

The heatable explosion containers allow for a determination of characteristics at temperatures of up to 200 °C |

| Spontaneous ignition |

Storage tests at hot temperatures and with sample containers of up to 12.8 l are to assess large volumes of > 1m³. |

Factors impacting characteristics and representative selection of dust sample

There are several parameters which influence the response of dust to an explosion. The two major factors are the grain size, which is defined by its median, and the moisture. The more grain size and moisture are decreasing, the more the dust will be inclined towards explosion as finer dusts are more easily flammable and show a fiercer response than those of a coarser grain. Therefore it is important to select a dust sample which covers even the most critical incident with regard to explosion protection. Generally, all inspections of dust settlements should use grain sizes of less than <250 µm, and those of stirred dust should use grain sizes of less than 63 µm. Nevertheless, we often inspect dusts supplied in a combination of grain sizes which is representative in relation to the relevant operating procedures. Thus the first step is always to determine the grain size and the humidity of each dust sample. Additionally, DEKRA Testing and Certification may carry out an immediate analysis or determine the specific contact resistivity if required. The sample volume required for the examination depends on the characteristics to be determined. The details stated below give some orientation how much dust is needed for which examination. The size of the dust sample needed in your specific case we will discuss with you before you send off the sample.

Individual examinations

All packages can be completed by individual examinations based on the individual hazard assessment. The determination of all characteristics always include the spread of the grain size and the moisture.

The following table gives an overview of the key characteristics and their testing methods plus the sample size needed for the examination.

| Parameter | Standard for testing | Amount needed |

|---|---|---|

Explosivness |

||

|

Median value (sieving analysis) |

VDI 2031 |

100 g |

|

Moisture |

Hygroscopic moisture |

100 g |

|

Explosivness |

DIN EN 14034-3 |

3 kg (20-l sphere) |

|

Lower explosion limit LEL |

DIN EN 14034-3 |

3 kg (20-l sphere) |

Prevention of potentially explosive atmosphere

|

||

|

Limit concentration of oxygen (LOC) |

DIN EN 14034-4 |

5 kg (20-l sphere) |

Prevention of iginition sources

|

||

|

Burning behaviour (class number) |

VDI 2263-1 |

200 ml |

| Smouldering temperature LIT (Minimum ignition temperature of a dust layer) |

DIN EN 50281-2-1 |

500 ml |

|

Ignition temperature MIT |

DIN EN 50281-2-1 |

400 g |

|

Minimum ignition temperature MIE (with/without inductivity) |

DIN EN 13821 |

1 kg |

|

Auto-ignition temperature |

DIN EN 15188 |

3 l |

|

Conductivity, specific resistance of a dust fill |

DIN EN 61241-2-2 or |

500 ml |

|

Grewer temperature (spontaneous ignition) |

VDI 2263-1 |

200 ml |

|

Assessment factor (impact sensitivity according to Lütolf) |

VDI 2263-1 |

100 g |

Explosion protection by construction |

||

|

Maximum explosion pressure pmax |

DIN EN 14034-1 |

5 kg (20-l sphere) |

|

Maximum pressure rise time, |

DIN EN 14034-2 |

25 kg or 100 l |

|

Dust explosion class St 1, St 2, St 3 |

DIN EN 14034-2 |

25 kg (1-m³ vessel) |

Analysis of hazardous goods |

||

|

ADR class 4.1, |

Combustion speede |

500 ml |

|

ADR class 4.2, |

Auto-heating capacity |

2.5 l |

|

ADR class 4.3, |

Substances which in contact with water emit flammable gases (UN test N.5) |

200 g |

Services

- Product test and certification

- Explosion protection

- Gas detectors

- Personal protective equipment

- Machinery

- GS quality seal

- Testing electric tools and machines

- Active medical devices

- Electrical appliances and household appliances

- Testing of luminaires and light sources

- Testing furniture

- Toys and child-care products

- Testing mechanical safety

- Functional safety

- EMC tests

- Explosion protection for plants

- Laboratory services

- Information and Training

Questions?

Mobil: 0151.62941022

thomas.burkhardt@dekra.com

Contact

Laboratory for product testing

Fon +49.711.7861-3454

products.de@dekra.com